To the untrained eye, a diecast miniature may seem like a simple toy, a scaled-down replica of an automobile. But for collectors and enthusiasts, it is much more: the materialization of a passion, a tangible piece of automotive history. What many fail to notice is the complexity, precision, and fusion of art and engineering hidden in every millimeter of the “perfect mini.” The journey, from the original concept of the real car to its diecast form, is an odyssey of talent and technology.

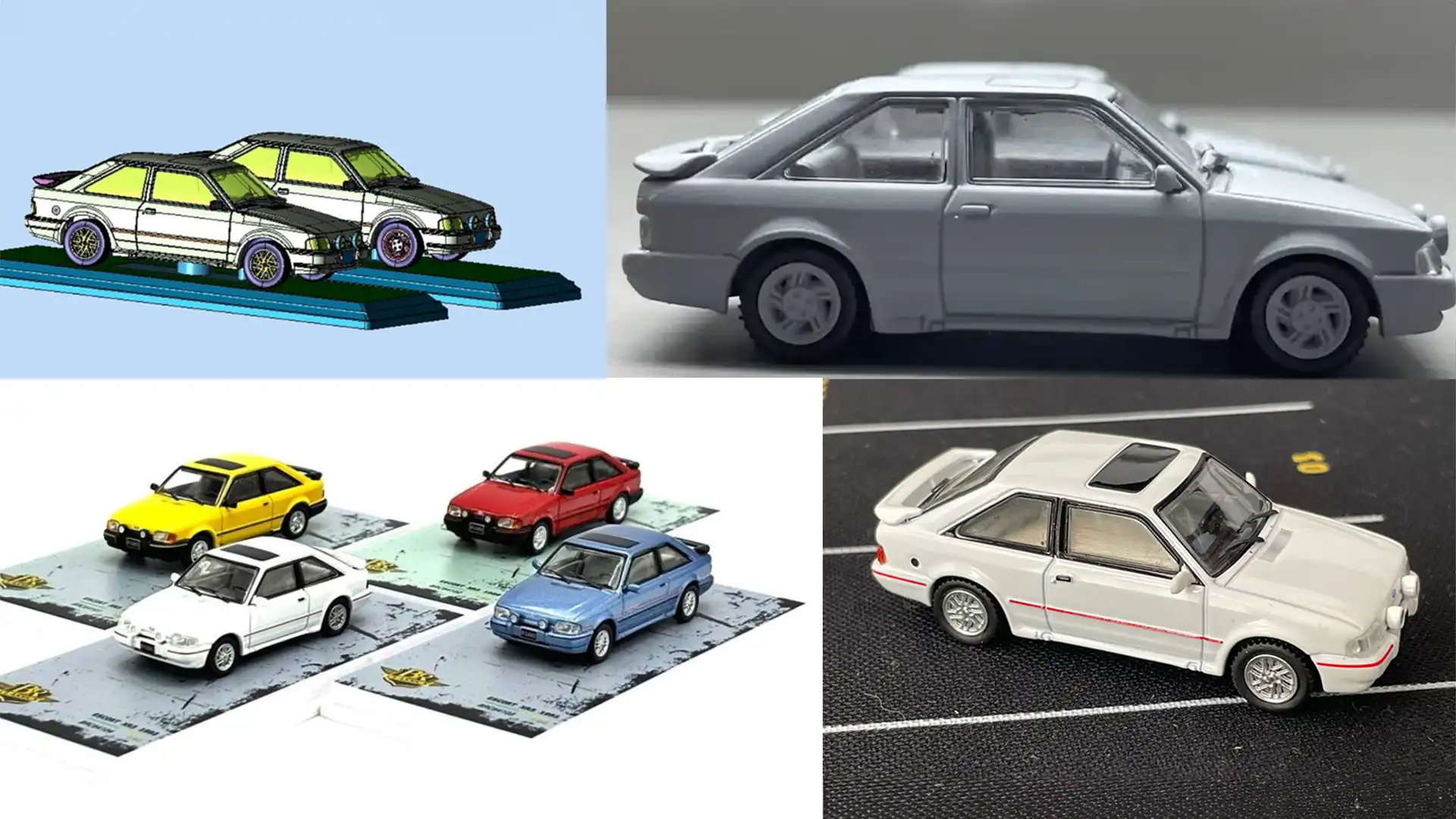

It all begins with design—the very essence of the vehicle that will be replicated. Shrinking a car is not enough. The true art lies in capturing the soul of the original model: its proportions, its signature lines, and the expression of its design, adapting them to a reduced scale. Miniature designers and engineers work tirelessly, often with direct access to CAD (Computer-Aided Design) plans from automakers. It is at this stage that artistic vision meets technical feasibility. Every curve, every crease in the bodywork, every interior and exterior detail must be meticulously translated, ensuring that the miniature is not just a copy but a faithful and instantly recognizable representation. The challenge is to preserve visual integrity, even when tiny elements become nearly invisible.

Once the design is digitally approved, engineering takes over. At the heart of diecast production are the molds—complex, incredibly precise structures usually made of hardened steel. The creation of these molds is a high-tech process, where advanced machining tools carve out the cavities that will shape the molten metal. Mold engineering is crucial: it determines not only the external form but also the perfect fits for windows, axles, interiors, and other components that will later be assembled. Small mistakes here can lead to massive defects in production. At this point, the material—a zinc alloy known as Zamac—is injected under high pressure into the heated molds, solidifying within seconds to form the main body and chassis. The precision of the diecasting process is a testament to metallurgical and mechanical engineering.

After the casting phase, the raw pieces undergo meticulous finishing. Burrs are removed, and the surface is prepared for painting. Applying the paint is another stage that demands great expertise, replicating not only the exact color of the original car but also its shine and texture. Skilled painters ensure that each layer is even and free of imperfections. Next comes assembly—a true test of both manual and robotic dexterity. Wheels, tires, axles, windows, mirrors, seats, steering wheels, and headlights—each small component is carefully fitted, many of them measuring only a few millimeters. The application of tampography or decals adds the finishing touches—emblems, racing stripes, and intricate graphics—elevating the miniature from a simple replica to a work of art in miniature form.

Thus, when we hold a diecast miniature, we are witnessing the synergy between design and engineering. It is proof that the passion for automobiles can be condensed and replicated with impressive fidelity, thanks to the tireless work of visionaries and technicians. Each piece is a micro-universe of precision, a celebration of form and function, and a reminder that true beauty often lies in meticulously executed details. For the collector, appreciating every curve and emblem of their miniature means connecting not only with the car itself but also with the extraordinary journey that brought it into existence.